The formation of metallic glasses, a unique class of non-crystalline solids, has fascinated materials scientists for decades. Unlike traditional crystalline metals, which exhibit a highly ordered atomic arrangement, metallic glasses possess a disordered atomic structure that grants them exceptional mechanical, magnetic, and corrosion-resistant properties. The atomic packing in these amorphous solids defies conventional metallurgical wisdom, offering a glimpse into the chaotic yet stable world of disordered materials.

At the heart of metallic glass formation lies the concept of rapid cooling. When a molten metal alloy is cooled at rates exceeding a million degrees per second, the atoms do not have sufficient time to arrange themselves into a crystalline lattice. Instead, they become frozen in a disordered configuration, much like the random arrangement of atoms in a liquid. This process, known as vitrification, results in a solid material with no long-range order, yet with short- and medium-range atomic correlations that contribute to its stability.

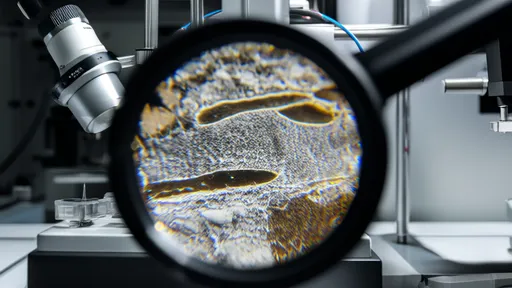

The atomic packing in metallic glasses is often described as dense but irregular. While crystalline metals have well-defined coordination numbers and symmetrical atomic environments, the coordination in metallic glasses varies from atom to atom. Advanced techniques like X-ray diffraction and neutron scattering have revealed that the local atomic arrangements in these materials often resemble icosahedral or other polytetrahedral clusters. These clusters, however, lack translational symmetry, leading to a structure that is densely packed yet devoid of periodicity.

One of the most intriguing aspects of metallic glass formation is the role of atomic size mismatch. Alloys that form glasses most readily typically consist of elements with significantly different atomic radii. This size disparity prevents the system from easily crystallizing, as the different-sized atoms cannot efficiently pack into a periodic lattice. Instead, they form a "confused" atomic arrangement where smaller atoms fill the gaps between larger ones, creating a mechanically stable but structurally disordered solid.

The concept of fragility in glass-forming liquids provides additional insight into metallic glass formation. Some liquid alloys exhibit strong glass-forming behavior, meaning their viscosity changes gradually with temperature, allowing for easier glass formation. Others are fragile glass-formers, with viscosity that changes dramatically near the glass transition temperature. The best metallic glass formers tend to be strong liquids, as this characteristic enables glass formation at relatively slower cooling rates, making industrial production more feasible.

Recent advances in computational materials science have shed new light on the atomic packing of metallic glasses. Molecular dynamics simulations can now track the movements of millions of atoms during the cooling process, revealing how local atomic arrangements evolve. These simulations show that the liquid-to-glass transition involves the progressive development of medium-range order, as atomic clusters form and percolate through the material. Interestingly, this medium-range order often involves chemical short-range order as well, where certain atomic species show preference for specific local environments.

The unique atomic packing of metallic glasses gives rise to their remarkable properties. Without grain boundaries or dislocations - the typical defects in crystalline metals - metallic glasses exhibit near-theoretical strength and exceptional elasticity. Their disordered structure also makes them highly resistant to corrosion, as there are no grain boundaries to serve as initiation sites for corrosive attack. Furthermore, the magnetic properties of certain metallic glasses make them valuable in transformer cores and other electromagnetic applications.

Despite these advantages, challenges remain in understanding and utilizing metallic glasses. The precise nature of the glass transition remains one of the great unsolved problems in condensed matter physics. Additionally, while small quantities of metallic glasses can be produced in the laboratory, scaling up production while maintaining amorphous structure presents significant engineering hurdles. Researchers continue to explore new alloy compositions and processing techniques to overcome these limitations.

The study of atomic packing in metallic glasses has implications beyond metallurgy. Similar structural principles may apply to other amorphous materials, from oxide glasses to polymers. Furthermore, understanding how disordered systems can achieve stability may provide insights into fundamental questions about the nature of the solid state. As characterization techniques improve and theoretical models advance, our picture of atomic arrangements in metallic glasses continues to evolve, promising new materials with tailored properties for advanced applications.

Looking ahead, the field of metallic glasses stands at an exciting crossroads. The growing ability to manipulate atomic packing through composition design and processing control opens possibilities for engineering glasses with specific combinations of properties. From biomedical implants to aerospace components, the potential applications of these remarkable materials continue to expand as we deepen our understanding of their disordered atomic architecture.

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025